.

Smart Engine for Industry 4.0

PREDICTIVE MAINTENANCE

With the maintenance and repairs of machines in the industry, the possible cost of stopping the plant is quite costly. Due to an unexpected failure, the machines may be inoperable for quite some time. In this case, it also leads to production losses and an increase in cost in the production companies that perform mass production. In order to avoid stopping production, it has reached a significant point in cost calculations to address predictive maintenance methods in which fault detection can be carried out using various test and analysis methods during the formation of faults.

The companies that perform maintenance are in the business:

Reduction in maintenance activities: 25 -30%

Reduction in deteriorations : 35-45%

Increase in production: 20-25%

Return on investment: 10 times higher

Maintenance planners face the issue of providing maximum machine availability every day. They also have the obligation to determine the amount of material consumed in the maintenance section when dealing with this problem, but to ensure that minimum repairs are carried out. Predictive maintenance solutions offer new capabilities for businesses: The possibility of a possible failure is calculated, taking into account the Datas, sensor monitoring and machine conditions. With these traces, corrective measures ensure the most effective planning. In addition, unplanned downtime can be avoided and resource use with personnel can be significantly reduced

In predictive maintenance, there are often oil analysis, infrared thermography measurement, ultrosonic testing, and undamaged inspections and vibration measurement and analysis

<1) Oil Analysis

By oil analysis, it is possible to determine which part has wear or a problem. Below the friction of the metals, low viscosity is shown as the main cause. The viscosity is monitored periodically and the chemical values of the oil are followed, looking at the characteristics of the oil, and the machine is serviced for oil change and fault removal at the point where it begins to lose its properties.

2) Infrared Thermography

Used to track hot areas of the system. Infrared Thermography is used in areas such as power plants, ovens, heating systems, where the temperature is very high. Temperature averages and variations are systematically monitored and a temperature level is pre-determined to stop any deceleration or operation of the system. If the temperature is found to be approaching the specified threshold, the system is serviced by performing a maintenance program.

3) Ultrasonik Test

It is one of the most useful and widely used methods in businesses. Assuming our hearing threshold is 20 Hz, it allows people to hear the sounds that we cannot hear by capturing and disconnecting Ultrasonic devices. By monitoring these sounds, regular reports and solutions for efficiency can be produced. This method allows compressed air leaks to be identified for vapor trap operational tests, bearing lubrication and damage detection.

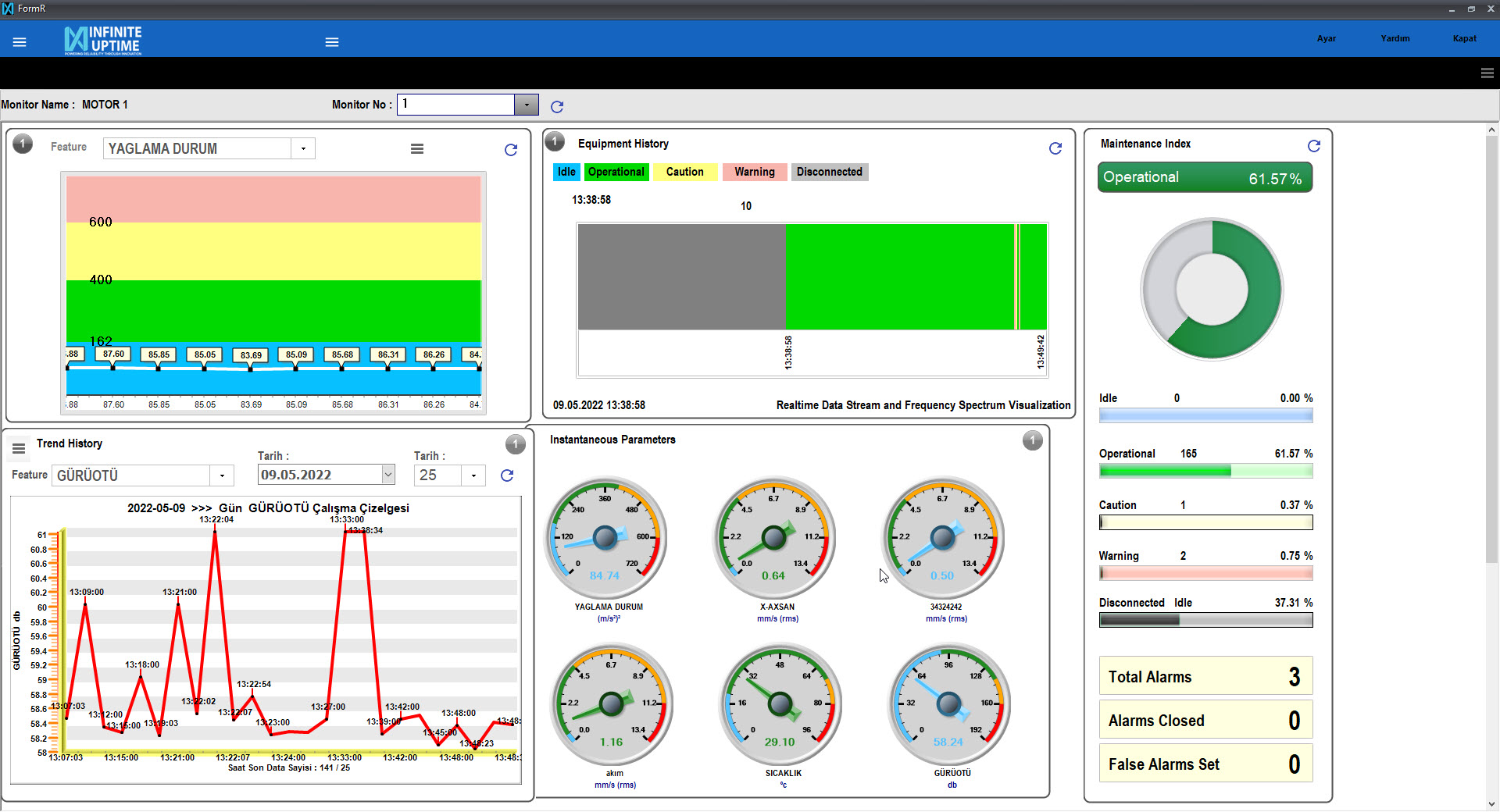

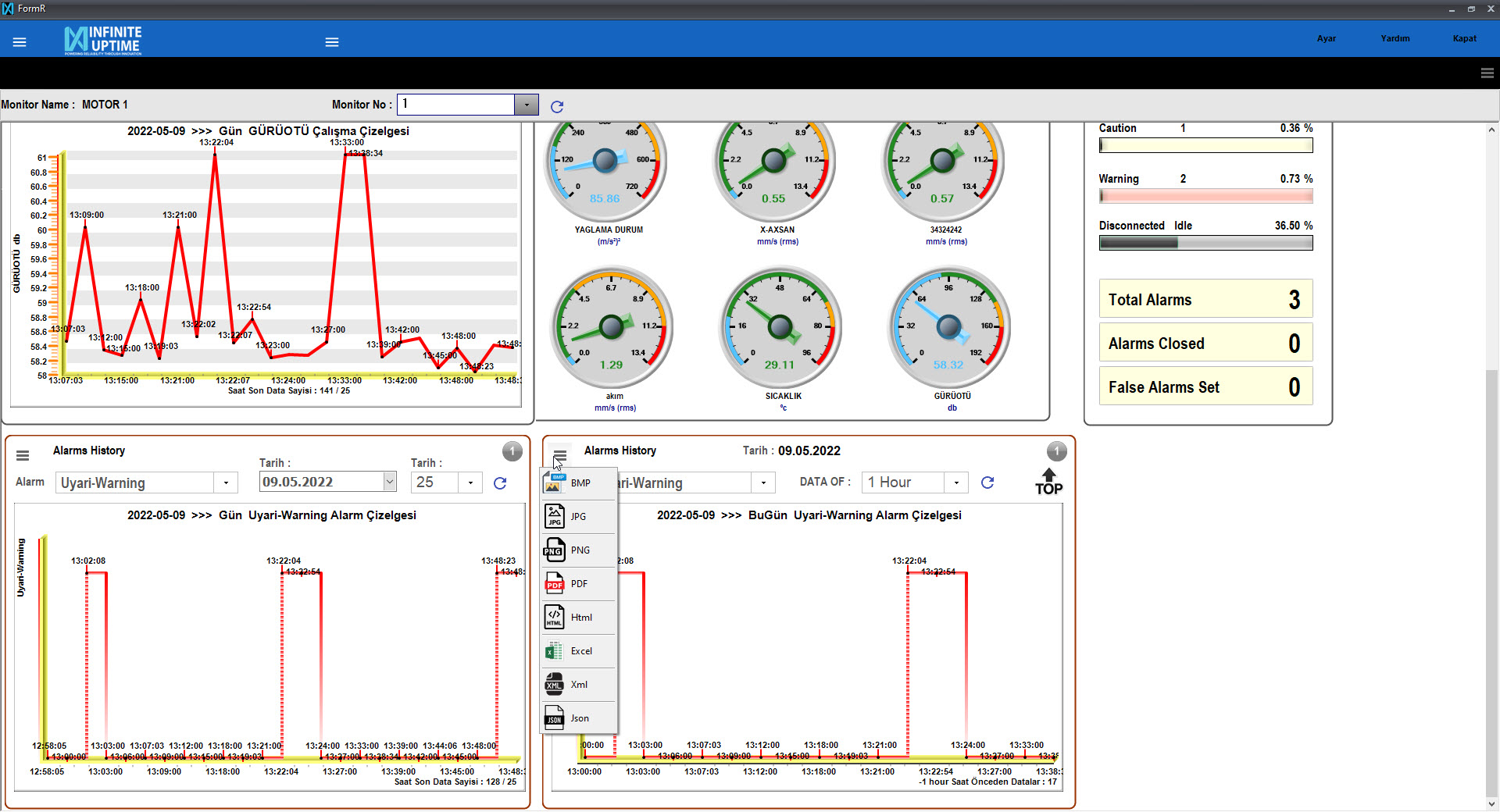

4) Vibration Measurement and Analysis

Vibration measurement and analysis, the most common predictive maintenance method, can be used for any machine with rotating parts. Problems caused by machine design or assembly are a major handicap to locate the fault. It is therefore necessary to carry out measurements periodically and to correlation the data obtained. The frequency and phase must be measured to perform this analysis. Each of the machine parts produces different vibrations. In the event of a fault, the conventional frequency signal is out of range, so information on what the fault is and which part is the cause of the fault can be accessed. Various software and devices are used when doing so.

What opportunities does Predictive Maintenance provide to businesses?

Increase in equipment life and efficiency.

Enables corrective maintenance for critical elements.

Reduces downtime in processes and devices.

Reduces labor costs.

Provides 8%-12% profitability compared to preventive maintenance.

Increase in energy savings.

Decrease in employee workload.

Return on Investment: 10 times

Reduction in Maintenance Activities: 25%-30%

Reduction in Breakdowns: 35%-45%

Increase in Production: 20%-25%

If machine failures can be diagnosed early during the maintenance process, it will not only prevent a bigger problem that may arise in the future, but also provide cheaper maintenance and treatment. In this way, companies can take precautions well in advance. With this system, innovative opportunities will emerge for companies.