.

Production check and test planting in pedal production plants

production stage;

Sequential production control

Poka-Yoke system

Product bar code

Shipping pallet system

With main headers for testing;

Lifetime Test

The Rejyness Test

Pin fatigue

Crytic characteristics of oil Job

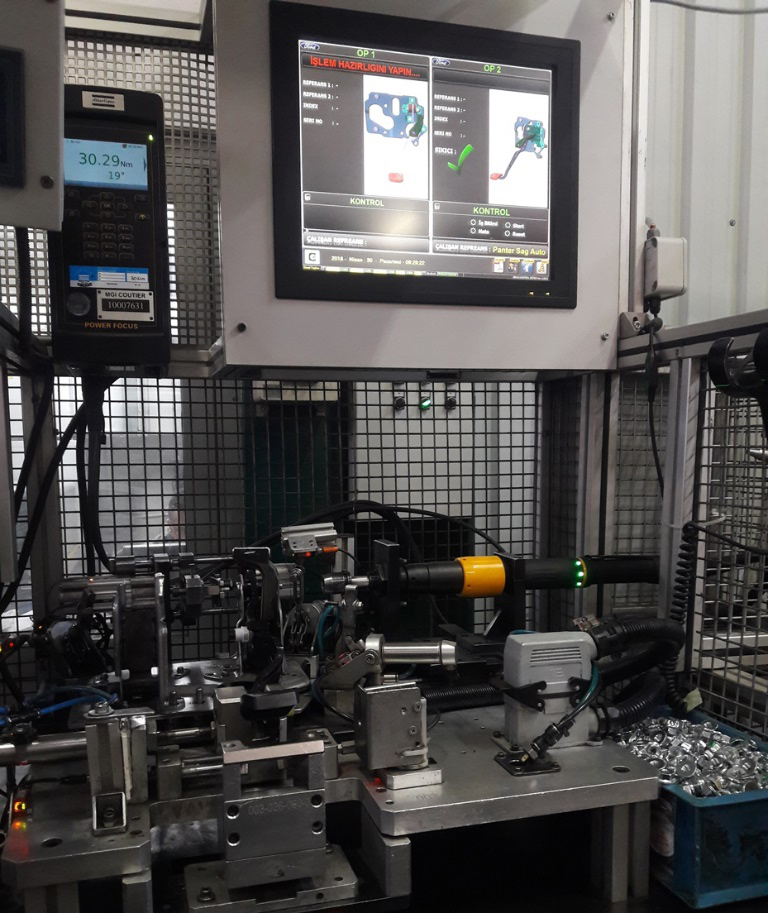

Examples of the above are the V36x Line Control System in the Sequential production System.

V36x Line Control System Summary Information

The V36x pedal Assembly Sequential Control System developed for MGI Coutier Filiale Bursa enables pre-defined pedals to be operated at the correct stations, to prevent them from jumping stations, to enter a station that should not be entered, and to retrace the respective pedals.

This project aims to prevent the pedals from jumping operations in any way, not entering the next operation before any operation is completed, and preventing operators from taking manual action and ignoring any errors occurring on the pedal.

The Inline Control System starts with the entry of a repair order from the packaging computer.

This means that the pedal part no. is to be used in the brake fitting post and the number of times to be manufactured is to be entered.

If there is a work order, the printer to the left of the operator in Station 1 (brake pedal lubrication) will issue a label and will operate when the subsequent stations are read this label.

When there is no work order, the operator will not be able to receive a label during lubrication and a warning message will appear on the display. In this case, a new work order must be entered.

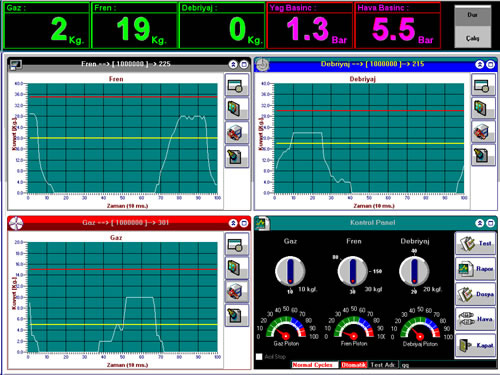

X85 pedal life test system

The pedal tester is designed to perform a physical life test of the brake, clutch and accelerator pedals and the carriers of the right, left-hand drive vehicles and automatic and manual gearshift vehicles.

In the physical life test, the system records the exact ranges and statistical values of the pedals.

The mechanical control of the system is provided by pneumatic, electrical, electronic and computer hardware and software.

The system has 5 components:

MECHANICAL FUNCTIONS

PNEUMATIC FUNCTIONS

ELECTRICAL FUNCTIONS

ELECTRONIC FUNCTIONS

COMPUTER AND SOFTWARE FUNCTIONS

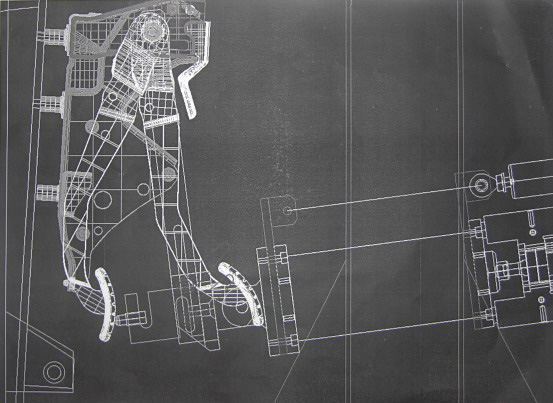

Pin Fatigue Lifetime Test

The most cretic point of the pedal, allowing the pedal to move under different forces, is the displacement of the pin, the test to observe the deformation.