.

Controls each product you produce and blocks any product that is outside your quality standards with traceability and error warning.

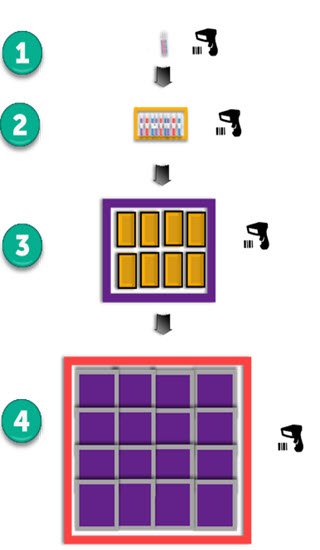

The system is placed in the boxes as shown step by step below.

The program tracks the entire process, and reads product bar codes with the step-by-step bar code reader, allowing the system and operator to move forward accurately and efficiently.

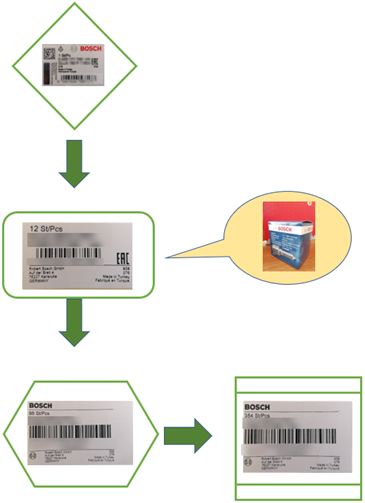

The processions specified in the flow diagram will proceed as described.

Products with type tags are required to first register their type and to be able to have the packaging carried out within this framework. If you're going to do the same type all the time, there's no need to rerout the label. When the type changes, the new type label must be read.

In step 2, the type tags read are placed in the blue box shown in the flow diagram. Typically, 12 items are placed in each small package here. However, in exceptional circumstances, packing can be done without placing 12 items in the box (when the product is finished, etc.). For such cases, a manual button is not automatically 12 products for packaging after type-reading, but is confirmed to indicate quantity after entering and confirming the quantity.

Stage 3; the small blue packages made in stage 2 need to be placed in the medium package. There are always 8 small packages placed inside the medium package and the following label is read.

In stage 4, the residual flow is indicated at the final stage in the diagram. Add as many products as required from medium packages and paste the label with the total amount into the large package.