.

The program tracks the product tree, allowing the product bar codes to remove bar codes, allowing the system and operator to move forward accurately and efficiently.

The DMC Barcode System controls each product you produce and blocks those outside your quality standards with traceability and error warning.

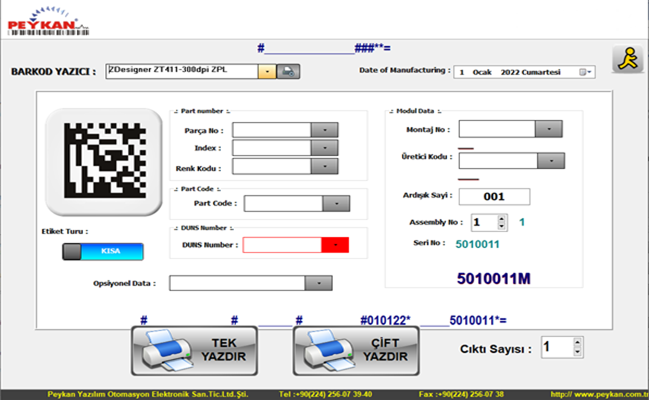

Label content is created in two ways.

LONG :Maximum data entry desired state

SHORT :Standard data entry desired state

LONG CODE ->#PartNumber#PartCode#DUNSNumber#DateOfManufacture*ModulData*=OptinalData

STANDART CODE ->#PartNumber###*ModulData*=OptinalData

The Serial No in the module data content is generated as a unique code for the creation according to the instructions specified in the automatic Serial ID content.

Finally, once the area to enter the confirmation code is entered, the optional label surface will be either unlabeled or double-label removed. Both label formats are designed to fit both wrap and join forms.

The system also allows more than one label to be removed.

If any of these steps are missing or incorrect, they will ALERT you as an incorrect entry with the warning and recording system, as they are below your quality standards. The data for the incorrect product is saved. If the product is error-free, the barcode is removed and registered to the system.