.

Digitize Your Weaving Production Process

This software, developed for weaving factories, allows you to track the entire production process from yarn to shipment in a digital environment. Every step in the production process can be monitored in real time and recorded. This increases workforce efficiency, reduces error rates, and makes production processes more transparent.

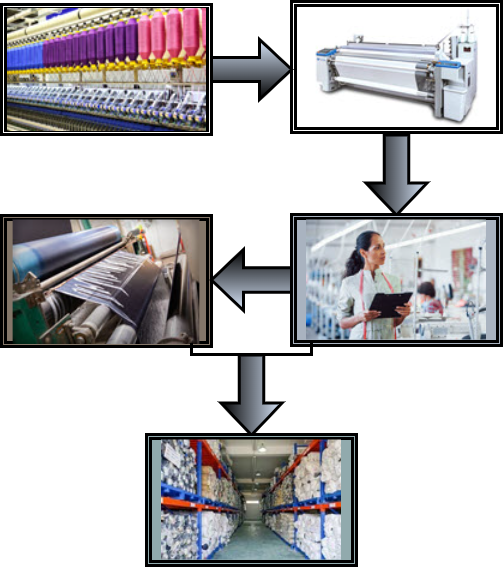

Production Process Flow

Yarn Definitions and Warehouse Entry

Detailed definitions of different yarn types can be made, and batch-based warehouse entries can be easily performed. The system supports inventory management methods such as FIFO and LIFO to ensure accurate and reliable stock tracking.

Daily Work Orders and Loom Tracking

Operator-based daily work orders can be defined for weaving looms. Real-time data such as which fabric is being processed on which loom, downtime reasons, and production performance are monitored to optimize the production process.

Inventory Management: Yarn, Grey Fabric, Finished Fabric

All stock movements from yarn to finished fabric are monitored in detail. Alerts for minimum stock levels, batch-based input-output transactions, stock reservations, and shipment integration are provided.

Quality Control

Post-production quality control forms are filled out digitally. Detected defects are classified, quality ratios are analyzed, and quality data is matched with production information for root cause analysis.

Finishing and Dyehouse Tracking

Fabric finishing and dyeing operations are tracked in detail through the system using batch numbers. All information such as color cards, recipes, and process durations are integrated and recorded.

Shipment and Packing List

Packing lists are created according to customer orders and shipments are easily controlled via barcode systems. Quick access to past shipments is also provided.

Advanced Reporting

Detailed reports on production, quality, inventory, and shipment processes can be generated. Exporting to formats such as Excel and PDF is supported. Filterable and graph-supported reports facilitate management decisions.